Forget Password?

Enter your e-mail address below to reset your password.

by Cotton Research Institute CRI

Egypt, Egypt

Egyptian cotton is long staple cotton. It’s the best type of cotton therefore occupies a high export value for the country. This position comes because the long-staple Egyptian cotton is characterized by its length, smoothness and durability, these properties come from the working of both genetic factors and natural factors available uniquely in Egypt, which makes such high-valued crop monopolized in Egypt. This provides an opportunity for Egypt in the highly competitive market of cotton production worldwide.

But unfortunately Egyptian production of cotton decreased over the past fifty years as a direct result of the decline in the price of cotton in the global market. The average area planted with cotton in the thirties of the last century was nearly 2 million acres, it gradually declined till it reached last year only 325 thousand acres.

Cotton R&D in Egypt focused on the development of strains of cotton, but did not bother to develop the cotton harvest mechanization. Which is what the world focus on when producing cotton. While cotton is harvested manually in Egypt, across the world it’s done using agricultural mechanization designed specifically for cotton harvest.

In a unique experiment executed by the Cotton Research Institute to study the impact of the use of mechanization available abroad to harvest Egyptian cotton, The efficiency of the harvested cotton ranged from 64% to 77% only. This low yield is due to the difference of methods of cultivation of Egyptian cotton and the difference in the strain itself in comparison to non-Egyptian cotton cultivated outside Egypt. That is the great motivation for designing automated machinery customized to meet the Egyptian cotton needs.

Design an automatic or semi-automatic machine to reap long-staple Egyptian cotton while you take into account the dimensions of the plant, properties of Egyptian cotton, and the harvesting efficiency rate should be over 90%.

The Institute for the Study of cotton annual experience three different machines on the market harvest automated foreign and the results were as follows:

|

Standards |

Manual Harvest |

John Deere 7260 |

John Deere 9970 |

|

|

Productivity (Quintals/Acre) |

7.1 |

4.58 |

4.68 |

5.47 |

|

Amount of Cotton Fallen Before Harvest (Quintals/Acre) |

0.4 |

0.4 |

0.4 |

0.4 |

|

Amount of Cotton Fallen After Harvest (Quintals/Acre) |

0.00 |

2.64 |

2.25 |

1.75 |

|

Amount of Cotton Growing on The Plant (Quintals/Acre) |

0.00 |

0.23 |

0.54 |

0.23 |

|

Time of Harvest (h:mm) |

6:00 |

0:48 |

1:25 |

0:23 |

|

Field Capacity (Acre/h) |

-- |

1.26 |

0.70 |

2.60 |

|

Personnel per Acre (Person/Acre) |

47 |

-- |

-- |

-- |

|

Total (Quintals/Acre) |

7.50 |

7.45 |

7.47 |

7.45 |

|

Harvest Efficiency |

99.9% |

64.51% |

65.92% |

77.04% |

It’s a direct result to the fact that these machinery weren’t designed to cultivate Egyptian cotton and the standards they are designed for is different.

As a result of the absence of the line separating one line of planted cotton from another and it’s about about 75 cm, the width of the tires of the Machines is greater than the distance between the cultivated lines, which causes the loss of many of the lines just when the machines march.

The first, second and third boll of the cotton is missed and not picked because the machines were designed for the average height for the 1st boll is 25 cm. However, in Egyptian cotton it’s as short as 18 cm.

Egyptian cotton can grow as tall as 160 cm but the machines are designed for plants that grow only up to 80 cm.

Egyptian cotton is planted in a fashion of 2 plants on the same line and the machines are designed for other fashion of cultivating cotton which is 1 plant on each line.

Sometimes the machines contaminate the yielded cotton when certain lubes are missing from the spindles.

Machines that harvest cotton throw suction don’t suit Egyptian cotton because cotton sticks too firmly to the flower and it’s done efficiently only throw spindling.

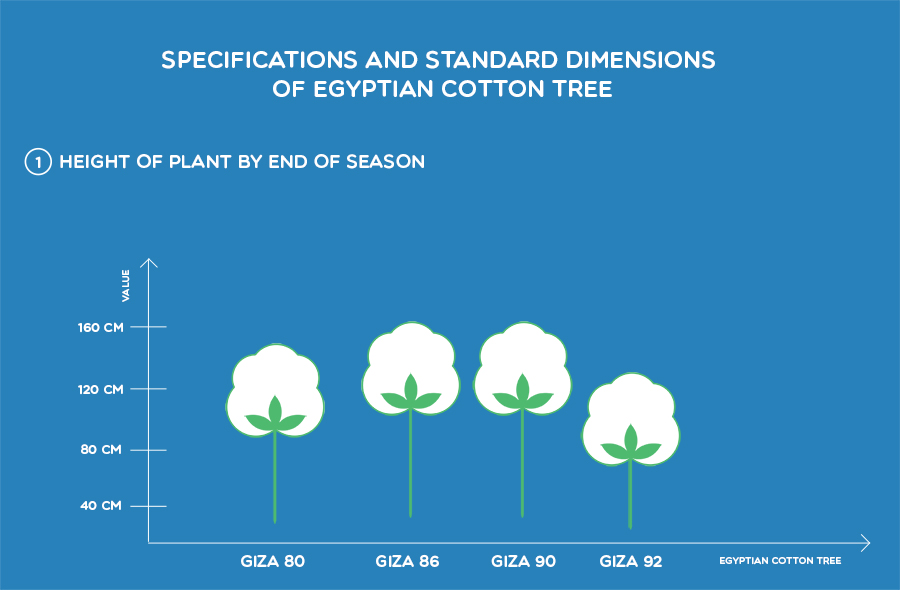

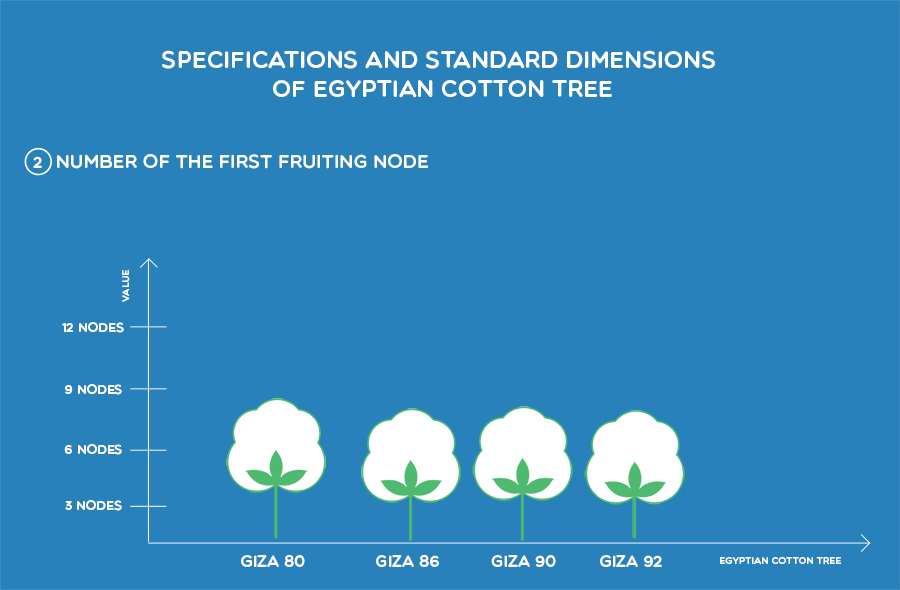

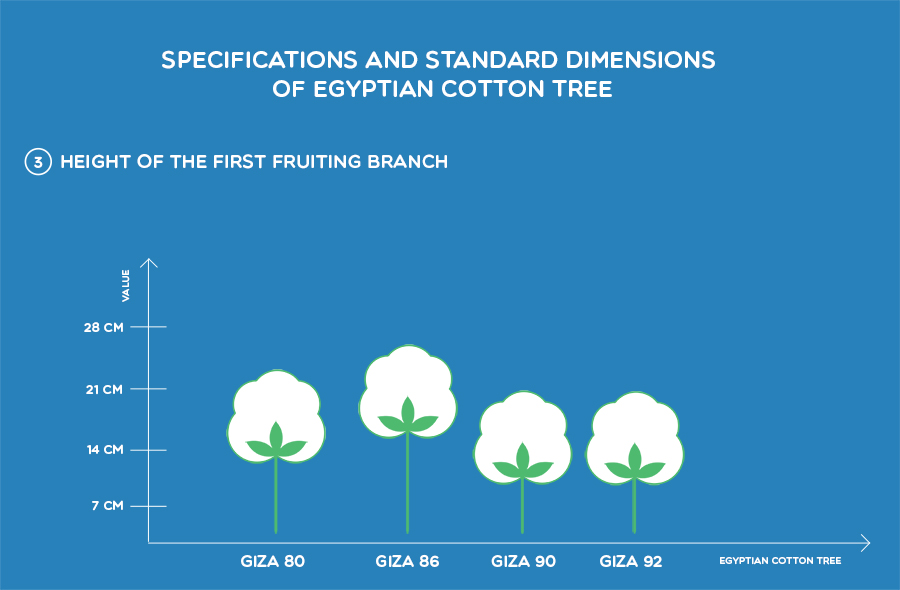

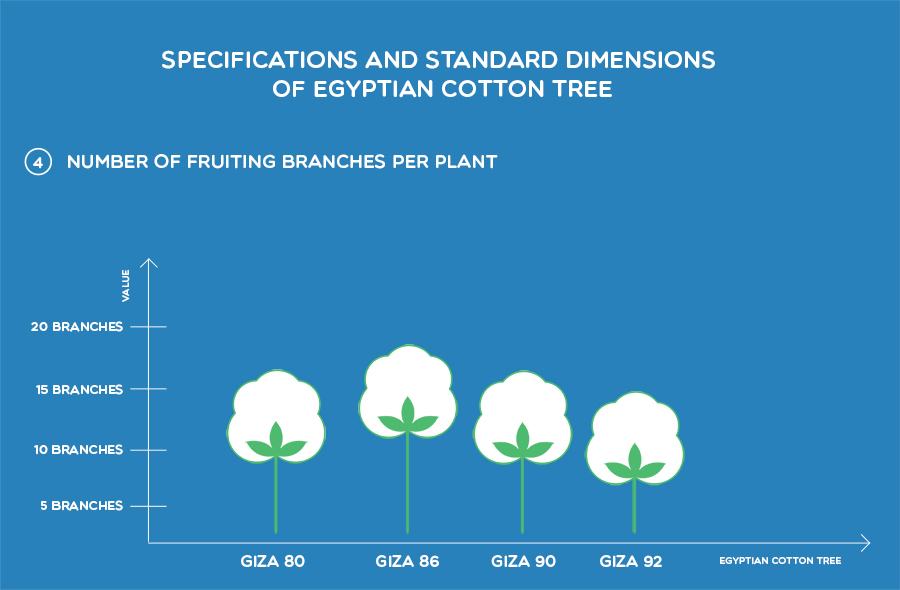

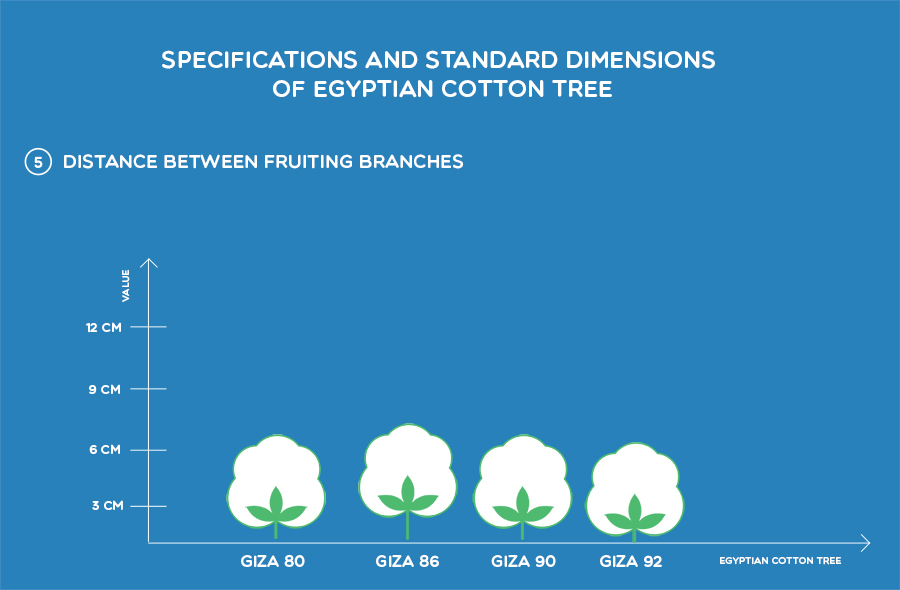

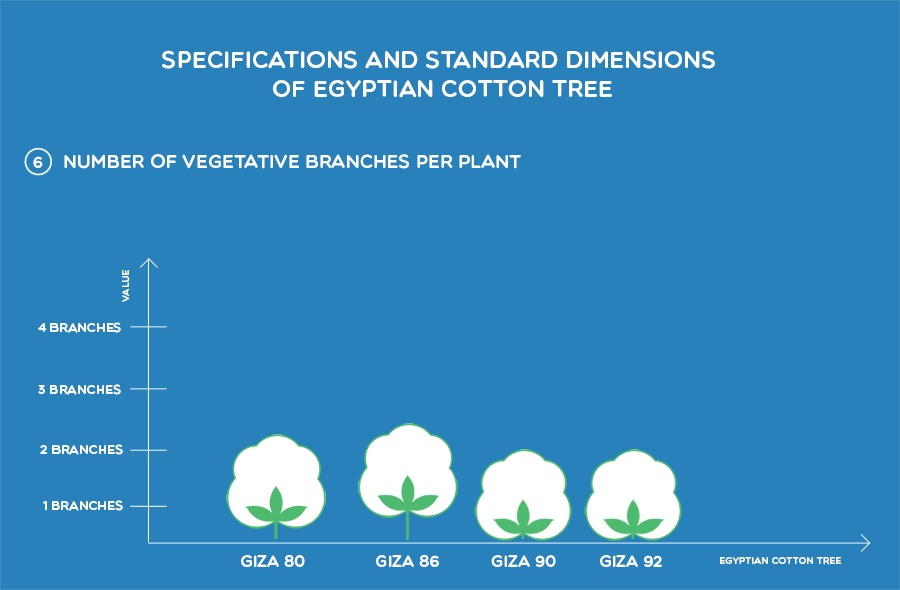

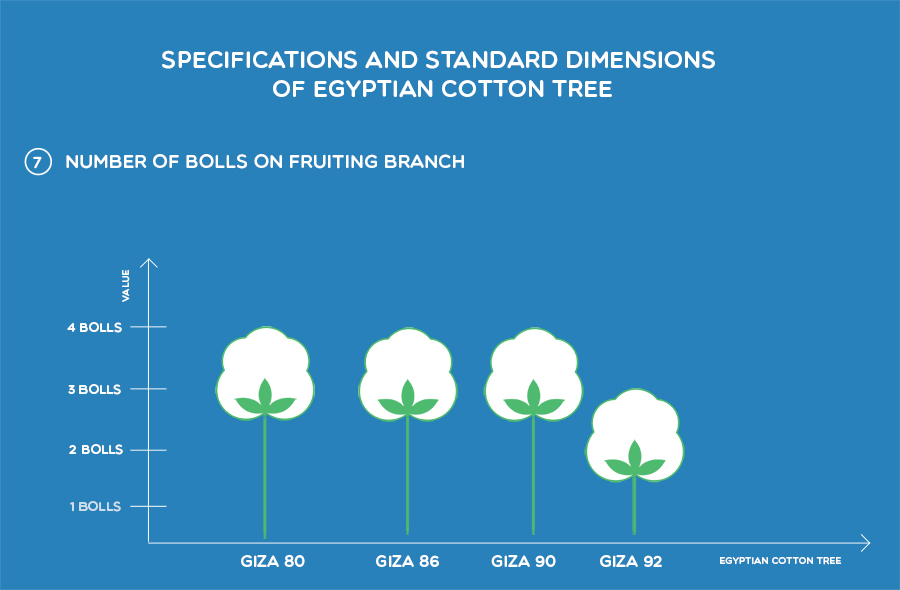

Specifications of vegetative and fruiting varieties of Giza Cotton 80, Giza 86, Giza 90 and Giza 92 strains.

|

No. |

Characteristic |

Giza 80 |

Giza 86 |

Giza 90 |

Giza 92 |

|

1 |

Height of plant by end of season |

130 - 140 cm | 140 - 160 cm | 130 - 150 cm | 120 - 130 cm |

|

2 |

Number of the first fruiting node |

7 - 9 Nodes | 6 - 7 Nodes | 6 - 7 Nodes | 6 - 7 Nodes |

|

3 |

Height of the first fruiting branch |

20 - 22 cm | 20 - 25 cm | 18 - 20 cm | 18 - 20 cm |

|

4 |

Number of fruiting branches per plant |

14 - 16 Branches | 15 - 17 Branches | 14 - 16 Branches | 14 - 15 Branches |

|

5 |

Distance between fruiting branches |

5 - 7 cm | 5 - 8 cm | 5 - 7 cm | 5 - 6 cm |

|

6 |

Number of vegetative branches per plant |

1 - 2 Branches | 0 - 2 Branches | 0 - 1 Branch | 0 - 1 Brach |

|

7 |

Number of bolls on fruiting branch |

2 - 4 Bolls | 3 - 4 Bolls | 2 - 4 Bolls | 2 - 3 Bolls |

|

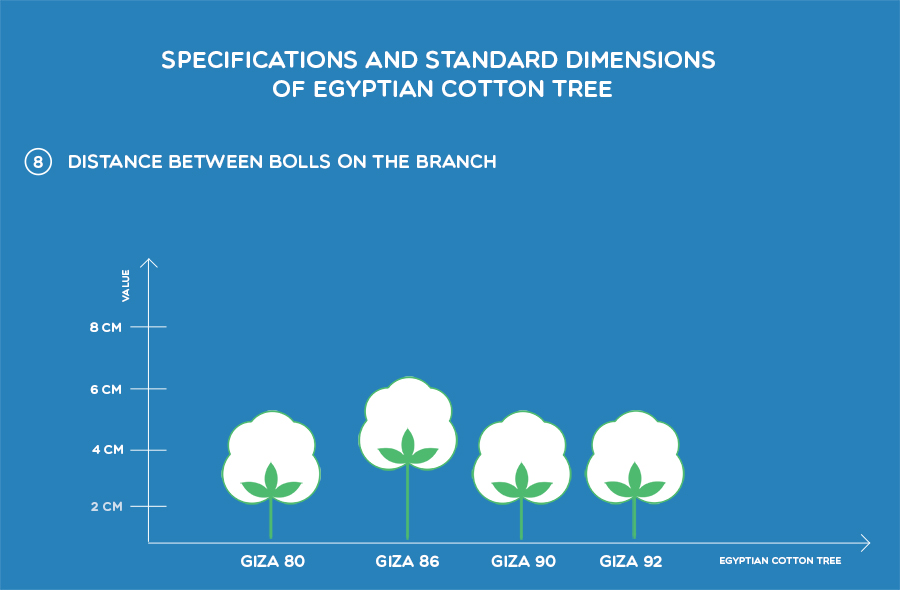

8 |

Distance between bolls on the branch |

3 - 5 cm | 4 - 6 cm | 3 - 5 cm | 3 - 5 cm |

|

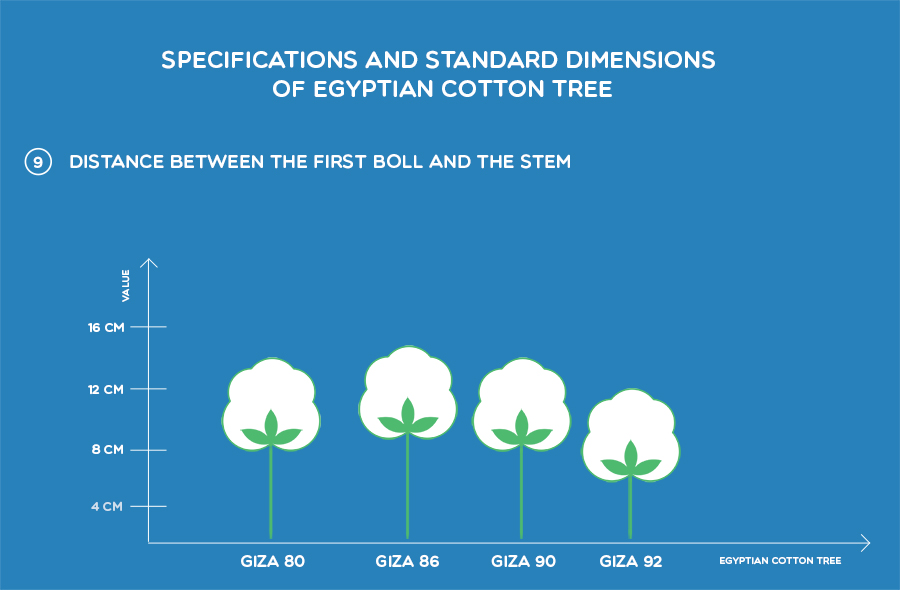

9 |

Distance between the first boll and the stem |

12 - 14 cm | 12 - 15 cm | 12 - 14 cm | 10 - 12 cm |

|

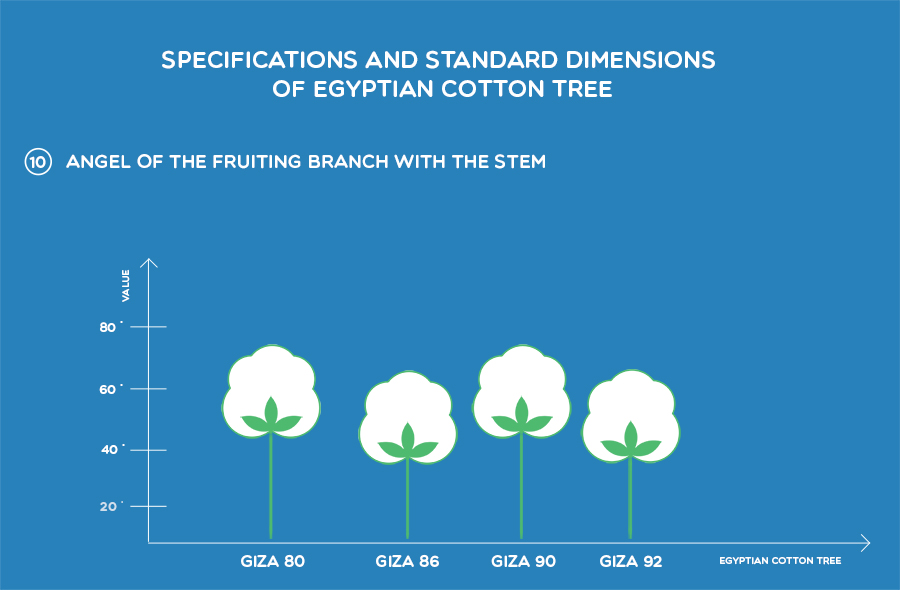

10 |

Angel of the fruiting branch with the stem |

75° | 65° | 75° | 65° |

|

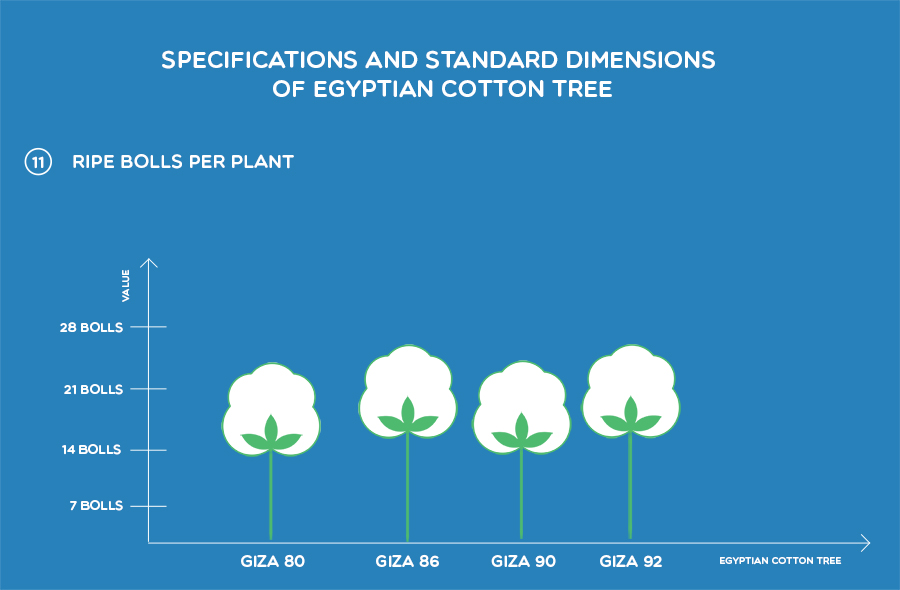

11 |

Ripe bolls per plant |

18 - 23 Bolls | 20 - 25 Bolls | 18 - 23 Bolls | 20 - 22 Bolls |

|

12 |

Open bolls per plant |

15 - 20 Bolls | 15 - 20 Bolls | 15 - 20 Bolls | 18 - 20 Bolls |

|

13 |

Closed bolls per plant |

3 - 5 Bolls | 4 - 6 Bolls | 3 - 5 Bolls | 1 - 2 Bolls |

|

14 |

Distance of fruiting area |

85 - 100 cm | 90 - 110 cm | 85 - 100 cm | 90 - 100 cm |

|

15 |

Weight of boll |

2.8 - 3.0 g | 2.8 - 3.2 g | 2.8 - 3.0 g | 2.8 - 2.9 g |

|

16 |

Days for the boll to flower |

65 - 70 | 75 - 80 | 65 - 70 | 70 - 75 |

|

17 |

Days of the curve of flowering |

35 - 50 | 45 - 60 | 35 - 50 | 45 - 60 |

|

18 |

Days the first bolls takes to flower-open |

110 - 120 | 120 - 130 | 110 - 120 | 120 - 130 |

|

19 |

Rate of the first harvest after 150 days |

70 - 80% | 45 - 55% | 70 - 80% | 60 - 70% |

|

20 |

Period the plant spends in soil |

150 - 165 Days | 170 - 190 Days | 150 - 165 Days | 160 - 170 Days |

Financial incentive from the Acaddemy of scientific research and technology, and Technical assistance from egyptian cotton research Inistitute.

If your organization is facing a pressing challenge, please submit it by clicking here and follow the instructions.

Share your ideas and get help

Yomken works with people who have brilliant ideas for innovative products and who are looking for financial, collaboration or marketing support to complete these ideas. Our platform helps you to get the needed PR and marketing for free! You may also get inspired by the challenges posted by others to solve them and get awarded in return!

Yomken enables you to find for innovative solutions outside the boundaries of your organization. Open-innovation enables you to use the power of social networking and the wisdom of the crowd. If you are a CSR department or a donor agency, you may also sponsor the solution of social challenges!

Yomken provides you a range of innovative products and ideas by some of the most innovative entrepreneurs in the world. You can support your favorite entrepreneurs by sharing or possibly collaborating with them to improve or complete their products!